Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

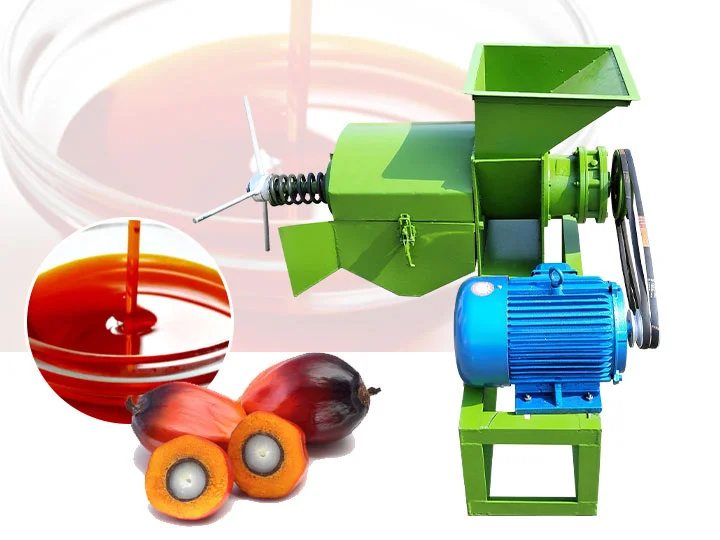

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

peanut oil extraction machine oil processing plant

- Product Using: Producing Peanut Oil

- Type: Peanut Oil Processing Plant

- Main Machinery: Peanut Oil Processing Plant Machine

- Automatic Grade: Automatic

- Production Capacity: 20~2000T/D

- Model Number: Hd-OIL

- Voltage: 380v/50Hz

- Power(W): up to specification

- Dimension(L*W*H): up to specification

- Weight: up to specification

- Certification: ISO,SGS,BV

- After-sales Service Provided: Engineers available to service machinery overseas

- Function: peanut oil extraction machine

- Capacity Model: 10T/H,30T/H,45T/H,60T/H,80T/H,100T/H

- Suitable material: peanut

- Patent product: Yes

- Patent No.: ZL2007 20092291.7;

- Fully automatic: Yes

- Technology: Top technology in China

- Technology support: life time

- Warrenty: one year

- After-sale service: Offering installation and debugging

Groundnut Oil Manufacturing Process With Flowchart

Step 1: Cleaning. After harvesting groundnut are received at processing facilities. Batches of harvested peanuts will contain whole peanuts in the shell, some shelled peanuts, and foreign objects (e.g., leaves, nodes, weed seed, etc.). The peanuts are then cleaned using cleaning machine so that oil is not contaminated with foreign materials.

Therefore, it is essential to equip the peanut oil production plant with professional edible oil refinery equipment to get them off and obtain the refined high-quality peanut oil. Groundnut Oil Processing Flowchart. Cost of Groundnut oil extraction machine: Generally, the cost of Groundnut oil extraction machine will be approximately Rs 1.8

Groundnut Oil Extraction Plant | Peanut Oil Processing | Oil

Groundnut Decorticator. Groundnut decorticator machine is used to remove the hard shell of peanuts and get red skin peanut kernels automatically. The shelled peanut kernel can be applied to the peanut oil production line. Groundnut decorticator is versatile in shelling not only peanuts but other oil seeds like almonds, sunflower seeds.

Fragrant Peanut Oil Production Line. The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved “no chemical

Choose Right Groundnut/Peanut Oil Extraction Machines

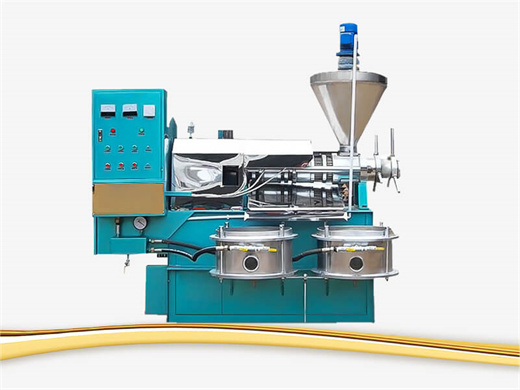

Small Screw Oil Press Machine - suitable for medium and small scale groundnut oil production line. Hydrualic Oil Press Machine - suitable for high quality oil production line or cold pressing line. The peanut oil press machine provided by HongdeMachinery has high quality and good production efficiency. Its capacity is 5-200ton/d per set.

Groundnut Oil Mill Plant. GOYUM SCREW PRESS is a leading manufacturer of groundnut / peanut / earthnut oil mill plants. We have exported oil mill machinery and equipment for customers around the world. Our groundnut oil extraction machines are successfully running in India, Nigeria, Tanzania, Chad, Senegal, Cameroon, Ethiopia, Niger, Ghana

peanut oil press machine for sale/large peanut oil processing

Large peanut oil processing plant flowchart. The complete peanut oil extraction production line generally includes steps such as cleaning, shelling, roasting, chopping, oil extraction, filtering, and filling. Cleaning. Raw peanuts with shells will contain certain impurities such as sand, stones, etc.

Recommended reading: Peanut oil processing plant. Peanut oil pretreatment and pressing machine. Although the peanut pretreatment machine is necessary, the peanut oil press machine is also important. As the core equipment of the peanut oil pressing production line, peanut oil press machine plays a huge role in the whole peanut oil pressing process.

Groundnut Oil Press Peanut Oil Extraction Plant - Vegetable

Groundnut Oil Press Peanut Oil Extraction Plant Section Introduction: We can provide the equipments to process different capacity of peanut groundnut They bring unrivalled experience to bear in producing accurate drawings detailing foundation loadings, building dimensions and overall plant layout designs, tailor made to

Peanut oil extraction usually refers to two different methods: expeller pressing and solvent extraction. These two methods usually are used together. Peanut oil expeller is a little similar to the meat grinder nowadays. When pressing, peanuts are put into the grinder, and high pressure and strong force are added as the screw turns and moves.

- What is peanut oil processing technology?

- This chapter covers the technology used for processing peanut oil. It starts by explaining the pretreatment technology and peanut pressing technology for high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- How is peanut oil extracted?

- Mechanical pressing can extract 85% oil and the remaining oil is extracted by the solvent extraction method. According to mechanical pressing technology, you can divide the peanut oil production process into three phases. These are peanuts preparation, pressing and crude oil refining. Step 1: Cleaning Step 2: Dehulling Step 3: Cooking

- What technology is used for extracting peanut oil?

- The leaching method, also known as the extraction method, is the technology used for extracting peanut oil. It involves using certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials, eventually separating the fat from the materials.

- What is the production flow of cold pressing peanut oil?

- The production flow of the cold pressing process of peanut oil is shown in Fig. 3.3. The temperature rises from 60 to 90°C during the process, and the oil/residual oil ratio of the system decreases gradually, reaching 4.5% at 90°C (as shown in Fig. 3.4).

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.