Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

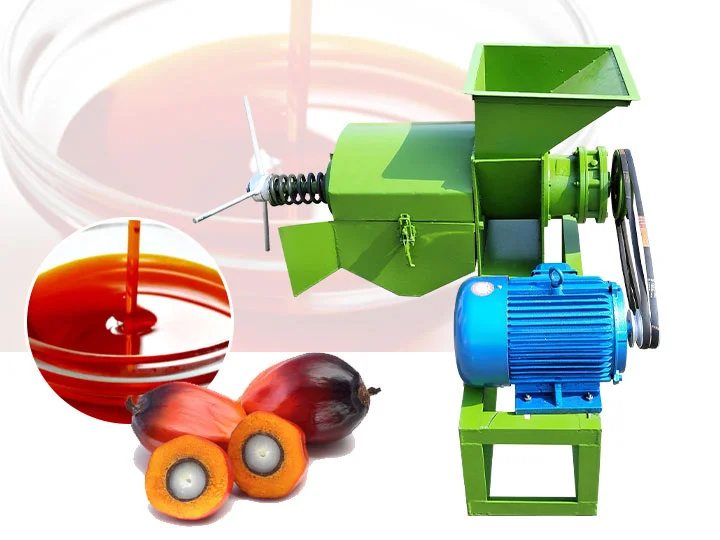

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

continuous peanut oil extraction refining equipment plant

- Product Using: Producing Peanut Oil

- Type: Peanut Oil Extraction Plant

- Main Machinery: Peanut Oil Extraction Plant Equipment

- Automatic Grade: Automatic

- Production Capacity: 10-1000MT

- Model Number: Solvent extraction method

- Voltage: 380V

- Power(W): According to capacity

- Dimension(L*W*H): According to capacity

- Weight: According to capacity

- Certification: CE and ISO

- After-sales Service Provided: Engineers available to service machinery overseas

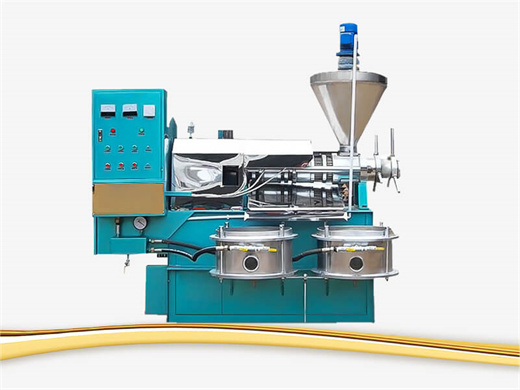

- Item: Screw peanut oil press machine

- Supplier type: Manufacturer

- Manufacturing experience: 19 years

- Steel type: MiId steel and SS

- Raw materials: Peanut/ peanut kernel

- Fina product: High quality cooking oil

- Processing method: Machanical press

- Handling capacity: 10-1000MT

- Model type: Continuous

- Main market: Africa, Aisa

Oils Fats Refining Equipment and Turnkey Plants

We can provide edible oil refining plant equipment with capacity ranging from 50 t/d to 4,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc. Refining is the last step in edible oil processing.

We can provide you the turn key project of the whole peanut oil extraction plant from 20 to 2000TPD . As manufacturer of peanut oil extraction plant, we can offer whole line or parts of peanut oil extraction plant with general capacity from 10TPD to 6000TPD. For special capacity, our engineers can also help you design and install workshop

Novel low-temperature continuous phase-transition extraction process

First of all, peanut oil has reached the national standard of leached peanut oil without any refining, and the content of unsaturated fatty acids is richer (83.35%). Second, the oil was rich in resveratrol (0.608 mg/kg) and plant polyphenols (28.60 mg GAE/kg), and oleic and linoleic acids were the major unsaturated fatty acids in low-temperature continuous phase-transition oil.

In general, there're 3 types of peanut oil refinery plant, batch type, semi-continuous and full-continuous. 1-2-3-5-10TPD batch type peanut oil refinery plant. 10-15-20-25-30-50TPD semi-continuous peanut oil refinery plant. 50-80-100-150-300-600-2000TPD full-continuous peanut oil refinery plant. Different capacity peanut oil refinery machine

Peanut Oil Processing Technology

After sedimentation, the crude oil is pumped into the frame filter for filtration, and the filtered product oil will be filled and packaged by a filling machine to form superfine fragrant peanut oil products (Fig. 3.9). Download: Download full-size image; Figure 3.9. Flow chart of equipment for superfine fragrant peanut oil production.

1-10tpd small scale peanut oil refining machine is a widely used edible oil refining machine which is suitable for various vegetable and animal oils, such as soybean oil, peanuts oil, sunflower oil, rape seeds oil, cottonseeds oil, coconut oil, rice bran oil, palm oil, palm kernel oil, etc.

Batch Type Small Edible Oil Refining Plant, Oil mill

Features of Batch Type Edible Oil Refining Equipment. Compact Setup: The equipment is designed to be modular, making it easy to install, operate, and maintain. Flexible Configuration: Allows for easy modification to handle various types of crude oils and refining processes. Batch Processing: Operates in batches, ideal for small-scale edible oil

Continuous peanut oil refining machine 3D diagram. Henan Doing Company is a leading designer, manufacturer and exporter of edible oil refinery plant in both continuous type vegetable oil refinery plant and batch type vegetable oil refinery plant. Next you will see the continuous peanut oil refining process.

Novel low-temperature continuous phase-transition extraction process

Physicochemical analyses of peanut oil Assays were performed to determine colour, acid values, peroxide values, iodine values and saponification value of peanut oil in accordance with GB1534-2017 [17]. Note that this is an officially recognized set of Chinese criteria to determine the physicochemical properties and quality stan-dards of peanut oil.

We can supply three types peanut oil refining machine for people to choose, they are: 1-20tpd batch type peanut oil refining machine, 20-50tpd semi- continuous peanut oil refining machine and 50-600tpd fully continuous peanut oil refining machine. No matter what kind of refining equipment you need, we can provide you with the suitable equipment.

- What is peanut oil production line?

- The peanut oil production line is the extraction process of fragrant oil from peanut kernel by adopting the unique pressing technology. Peanuts are high-oil-containing oilseeds. Currently, the unique pressing processes are suited to extract high-flavored edible oils, which has really achieved ¡°no chemical production¡±.

- What is peanut oil processing technology?

- This chapter covers the technology used for processing peanut oil. It starts by explaining the pretreatment technology and peanut pressing technology for high temperature and cold pressing peanut oil. It then discusses the peanut oil extraction technology, which includes leaching and separation technology.

- What technology is used for extracting peanut oil?

- The leaching method, also known as the extraction method, is the technology used for extracting peanut oil. It involves using certain organic solvents that can dissolve fat to spray and immerse the oil-bearing materials, eventually separating the fat from the materials.

- How to extract residual oil from roasted peanuts?

- The residual oil was recovered using n-hexane solvent extraction after continuous pressing. Peanuts that had been roasted at 180 °C for 10 min were ground into powder, treated with n-hexane, and agitated at 200 rpm for 2 h. The process of extraction was repeated twice using n-hexane.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.