Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

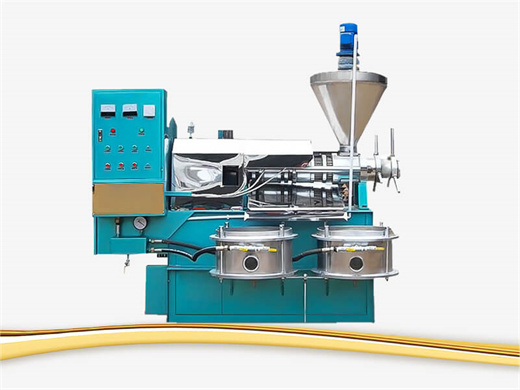

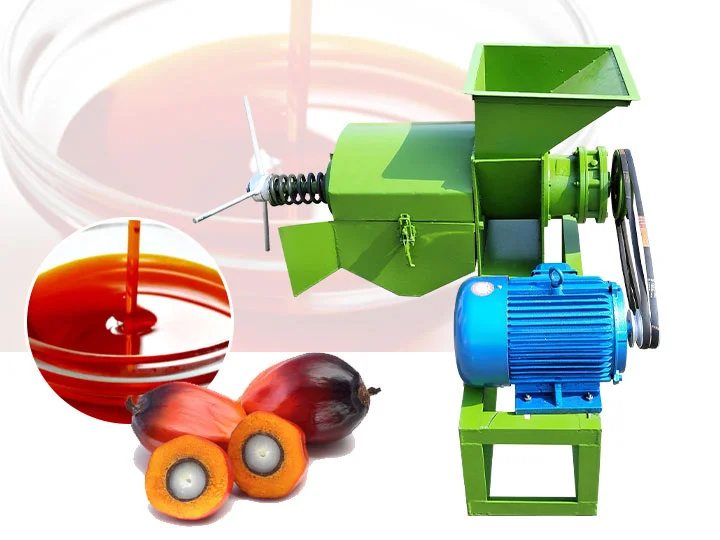

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

machine for business oil re-refining plant in mali

- Product Using: Producing Cooking Oil

- Type: Cooking Oil Refining Plant

- Main Machinery: Cooking Oil Refining Plant Machine

- Production Capacity:5TPD-100TPD, 500-2500kg/day

- Voltage:380V/50HZ,tripe phase

- Dimension(L*W*H):Depend on the model

- Weight:140kg-350kg

- Core Components:Motor, Engine

- Oil type:Flax Seed Oil, crude oil, Rap seed oil, Tea Seed Oil, Basil oil, SESAME OIL, Pinenut oil, oil, Almond Oil, walnut oil, Peanut Oil, Coconut Oil, OLIVE OIL, Palm Oil

- After-sales Service Provided:Engineers available to service machinery overseas, Field installation, commissioning and training, Video technical support, Online support

- Product name:sunflower oil refining machine

- Raw material:edible oil

- Material:Stainess Steel

- Function:oil refining machine

- Application:Edible Oil Refining

- Advantage1:Simple Operation

- Advantage2:high efficiency

- Name:Oil Refinery Equipment

- After Warranty Service:Video technical support, Online support

- Certification:CE ISO

- Project Location: mali

A set of 7TPD waste oil recycling refinery plant was

Machine installation. After the waste oil recycling refinery plant arrived in Mali, DOING professional engineer team got in touch with the Mali customer and began to provide technical guidance and training with the Mali customer to help him set up the waste oil recycling refinery plant project successfully.

In November 2023, we received positive feedback from customers in Mali, where a 7TPD waste oil refinery machine was installed successfully. Waste oil refinery machine installed in Mali 【Waste Oil Refinery Plant in Mali Project Details】 As we are aware, Mali, a landlocked country in West Africa, faces challenges regarding its fuel supply

A set of waste oil to diesel refinery plant shipped to Mali

On March 26, 2023, a set of 7TPD waste oil to diesel refinery plant was shipped to Mali. To ensure the working efficiency, safety and the diesel quality, the Mali customer also ordered the heat conduction oil furnace and solid catalysts, which were shipped to Mali together. Delivery site photo of a set of 7TPD waste oil to diesel plant to Mali

Used Lube Oil is defined as the petroleum-derived or synthetic oil which remains after the application of Lube Oil in lubrication, cutting purposes, etc. Lube Oil has a lot of usefulness for our machines, not just cars but other machines such as lawnmowers, and many others. It becomes Waste or Used Oil after it has been used, a time when

THERMOPAC, The True Turnkey Used Oil Re-Refining Plant

Re-refined Plant lube oil is environmentally friendly and can be re-refined many times over for maximum savings. Thermopac is the only company in the world to engineer, procure and construct the entire Re-Refinery Plant or treatment of used lube oil on true turnkey basis. We build skid mounted, continuous and fully automated waste free Re

The steps for distilling diesel from waste motor oil are: Pre-treatment. Dehydration and Light Ends Removal. Catalytic Cracking. Fractionation and Condensation. Refining and Desulfurization. The PPGT-DF Waste Oil Distillation Plant is capable of converting various types of waste oil feedstock into diesel fuel and other valuable byproducts

Oil Re-Refining | Used Oil Recycling | Safety-Kleen

1. Used Oil Pick-Up. More than 200 actual million gallons of used oil from auto service centers, fast lubes, car dealerships and factories arrives at our re-refineries each year. Both scheduled and emergency pick up service is available. The trucks deliver the used oil and the recycling process begins. 2.

This effectively closes the environmental loop for used oil, further enhancing its sustainability. 2. Environmental benefits. Capturing and re-refining used oil eliminates the risk of it getting into and harming the environment. Additionally, the carbon footprint of re-refined oil is lower than that produced from virgin crude.

Used Oil Re-Refining: Two Main Processing Steps - NORA, An

Most re-refiners in the USA use hydrotreating technology. The AVISTA OIL Group uses its exclusive patented technology in its three plants (Germany, Denmark, and USA); Avista technology is based on the Solvent Extraction Concept.. more Latest News . 5/22/2024 Momentum Environmental Announces Acquisition of T&R Environmental. 5/16/2024 The Used Oil World Unites: International Day at NORA 2024

Re-refining is the environmentally responsible way to manage used oil, reducing greenhouse gas and heavy metal emissions. Crystal Clean’s state-of-the-art oil re-refinery in Indianapolis, IN, commenced operations in 2012 and is permitted to process up to 75 million gallons of used oil per year. Used oil is transformed into high-quality Group

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.