Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

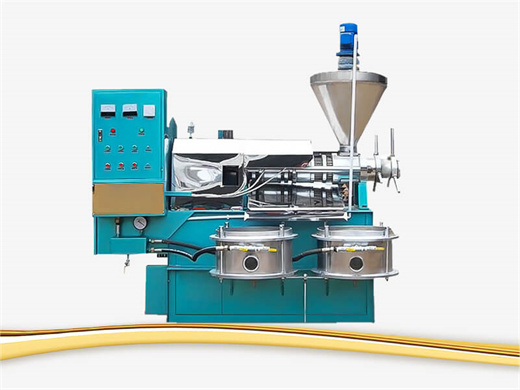

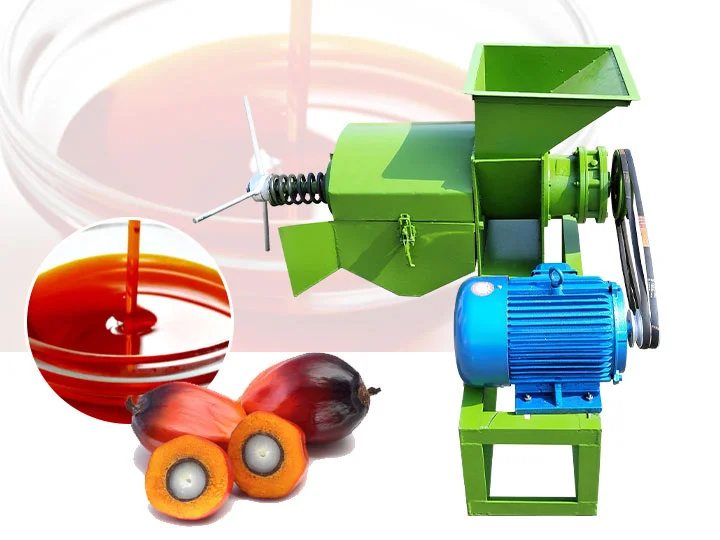

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

crude seed oil squeezing solvent production line in malawi

- Product Using: Producing Cooking Oil

- Type: Cooking Oil Production Line

- Main Machinery: Cooking Oil Production Line Machine

- Power(W):according the mode of the concentrated soya protein making machineDimension(L*W*H):according the mode of the concentrated soya protein making machine

- Weight:according the mode of the concentrated soya protein making machine

- Certification:CE,BV,ISOType name:concentrated soya protein making machine

- Final product:protein and oilProduction Process:pretreatment,solvent extraction,desolventizing,refining

- Steel material:carbon steel or stainless steel

- Process Feature1:at low temperatureProcess Feature2:at least two times dehulling

- Process Feature3:low temperature desolventizer

- Product standard:can meet the Europe market demandSupplier:professional manufacturer

- Brand:QI'E

- Project Location: malawi

10-100tpd crude oil production line in Malawi

10-100tpd sunflower seed oil processing production line. 10-200tons: Impurities in crude oil: 0.01%: Smell: natural oil smell: Vacuum degree: high vacuum: Color: light yellow: Pressing type: solvent extraction: Function: extract oil from seed: Squeeze type: sunflower seed oil processing production line: Residue in cake: less than 1%

The seed preparation area and the solvent extraction area are physically separated by a safe distance consisting of a controlled area and restricted area (NFPA, 2013).A typical plan view of the seed preparation process area, solvent extraction process area, and surrounding restricted and controlled areas is illustrated in Figure 8.1.

Sunflower Oil Production Line for Sunflower Oil Plant

De-shelled pressing-leaching technology is the key point of sunflower oil production line which avoids the negative impact of over-refining, high temperature, and acid and alkali effects on oils, so that the nutrients in the oil can be well preserved. For example, the content of vitamin E in de-shelled squeezed sunflower oil is 75.5mg/100g.

karanj seeds presser made oil production line in malawi. Use: seed oil; Type: seed oil production line; Production Capacity: 1tpd-30tpd; Model Number: YZYZ-5; Voltage: Design according to customer demand; Power(W): 11 KW; Dimension(L*W*H): 4935*1523*2664; Weight: Standard; Certification: ISO9001, BV, CE; Production Material: Stainless steel or

oil production line price 60/oil pressing in Malawi

Malawi Crude Oil: Production, 2014 2023 CEIC Data. Malawi Crude Oil: Production was reported at -27.710 % in Dec 2020 This records a decrease from the previous number of -17.630 % for Nov 2020 Malawi Crude Oil: Production data is updated monthly, averaging -1.940 % from Jan 2014 to Dec

3-1000tpd seeds oil press production line Malawi | Pressing. Our vegetable oil and fat refining line is used to refine various oils, including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, maize germ oil, and rice bran oil. This production line features a capacity of 30-1,000 tons of crude oil per day, and is able

sunflower oil production line oil refinery plant in malawi

Raw material: Soybean, Sunflower, Sesame, Palm, Cotton Seeds; Product: to make crude oil or refined oil; Solvent name: n-hexane; Capacity: from 5T to 2000T oil solvent extraction plant; Oil content in groundnut: about 44-55%; Oil residues: less than 1%; Function: getting oil and refining it; Manufacturing experience: 19 years experience

T-OPM-S10. $1,425.00. Pressed oil and extracted oil are the two main oils on the edible oil market. Pressing is to obtain oil by simply squeezing. the seeds, and physical squeezing maintains the natural color, aroma, flavor and nutrients. The extraction process is to completely immerse. Capacity:10ton/day. Oil Extruder parameter: Main shaft

soybeen oil production line machine manufacturer in malawi

Main machine of soybean seeds pretreatment line. 2. Soybean Cake Solvent Extraction Line. Solvent→extractor → mixed oil → 1st and 2nd evaporation → stripping tower → crude edible oil; Wet meal → DTDC toaster → cake. 3. Crude Soybean Oil Refining Process

Sunflower Oil Processing Steps. The processing characteristics of first-grade sunflower oil are: First of all, sunflower seeds are selected and cleaned to remove impurities, and then the seeds are de-husked and crushed. After that the embryo is flaked and steamed in the frying pan, the fried product is pre-squeezed out of the oil and the

- What is Malawi oilseed sector transformation (most)?

- The Malawi Oilseed Sector Transformation (MOST) programme aims to reduce poverty by facilitating changes in the cotton, groundnut, soybean and sunflower markets using a market systems approach.

- Does Malawi have agro-ecological suitability for production of oilseeds?

- Revised. Lilongwe: MoAFS. After considering the agro-ecological suitability of different areas in Malawi for production of oilseeds, two sets of analyses are done using nationally representative household-level data from the fourth Malawi Integrated Household Survey (IHS4) of 2016/17.

- Why are agro-ecological constraints affecting smallholder farmers in Malawi?

- Given the general agro-ecological suitability of much of the land in Malawi for production of these crops, the principal spatial constraints to smallholder farmers engaging in their commercial produc-tion are more likely to be linked to market access and the costs producers would face in order to profitably sell their oilseed.

- How many households participate in crop agriculture in Malawi?

- Source: Benson, Mabiso, and Nankhuni (2016). Source: Author¡¯s weighted analysis of 2016-17 Malawi Integrated Household Survey. Note: Observations (IHS4 survey sample households that engage in crop agriculture): 9,293.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.