Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

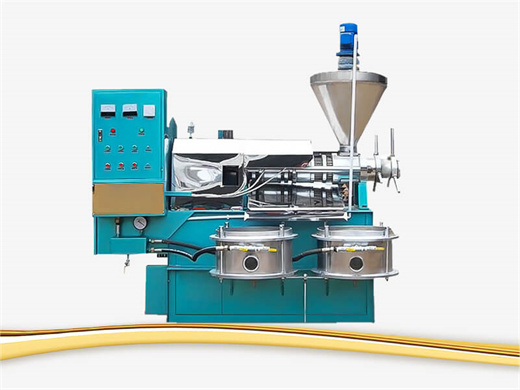

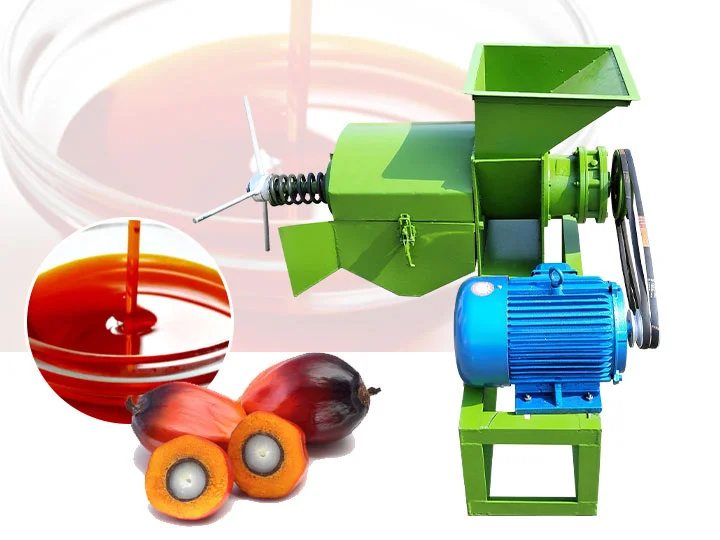

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

low residual oil rate corn germ oil solvent production line

- Product Using: Producing Corn Germ Oil

- Type: Corn Germ Oil Production Line

- Main Machinery: Corn Germ Oil Production Line Machine

- Model Number: HDXS211

- Industrial Use: Food, Food & Beverage Packaging

- Use: Noodle, Milk, Hamburger, Bread, Champagne, Chewing Gum, Sushi, Jelly, Sandwich, Sugar, Salad, cooking OIL, cake, Snack, Chocolate, Pizza, Cookie, Seasonings & Condiments, Canned Food, CANDY, Baby Food, PET FOOD, POTATO CHIPS, Nuts & Kernels, Other Food

- Paper Sealing & Handle: Patch Handle

- Custom Order: Accept

- Feature: Bio-degradable, Automatic Machine Making

- Material: 120gsm Recycled Brown Kraft

- Handle: Flat Paper Handle/ Twisted Paper Handle

- Size: Customized Size

- MOQ: 10000pcs

- Printing: Cutomised Printing

- Key words: Paper Bag Supplier

- Advantage: Environmentally friendly and recyclable

corn germ oil extraction line

The process flow of the pretreatment section of the corn germ oil production line: Process flow: corn germ → magnetic separation → cleaning → steaming and frying → pre-pressing → sent to the leaching workshop. The pretreatment section in the corn germ oil production line is more important because it directly affects the oil extraction

Usually the corn germ is around 8% in the total corn grain, and the corn germ’s oil content is approx. 50%. There are two common production methods for corn germ oil: pressing method, suitable for small and medium-sized corn oil producers, and solvent extraction method, suitable for large-scale corn oil producers.

Corn Germ Oil Production Line

Supplying on-site guide for mechanical & electrical installation and commissioning of corn germ oil production line. Corn germ oil has many benefits for the human body, is good for heart health, and is rich in vitamins and linoleic acid. Here is the corn germ oil production process. The corn germ oil production line includes 3 sections: 1.

Miscella treatment: Miscella is grease containing oil solvent. In order to remove the solvent in the oil, the solvent can be separated by evaporation and stripping (evaporation temperatures are different) a. Evaporation: First evaporation, the mixed oil concentration is 70-75%. Second steaming mixed oil concentration 85-90%.

Corn Germ Oil Solvent Extraction Plant for Producing High

5. Perfect condensation of solvent with low level of residual oil. Combined with the evaporation system, the solvent condensation system of the corn germ oil extraction production line can completely separate the raw corn germ oil and the solvent. The tail gas goes to the paraffin recovery process.

Easy ways to get the answers you need. Tel: +86-027-8790 7188. Fax: +86-027-8790 7188. Email: support@htoilmachine.com. Features. Technical Data. Application. Services. Adopts the most advanced corn germ oil extraction technology to ensure high efficiency, economical and reliable crude germ oil extraction process.

Oil and protein recovery from corn germ: Extraction yield

The residual oil and phenolic contents in the meals after defatting treatment could thus play a detrimental and complex role in the protein extractability. These results are consistent with the 20–28% crude protein extracts and the 25–28% extraction yields reported by Hojilla-Evangelista (2012) from corn germ defatted by hexane RT. 3.3.2.

The extraction of corn germ oil was evaluated using pressurized propane as solvent in semi-batch process as an alternative approach to organic solvent extraction. The effect of temperature (20, 40, 60 °C), pressure (20, 60, 100 bar), particle size and confinement time were studied. Moreover, the extraction kinetics for the pressurized solvent were determined. Temperature and pressure had no

Corn Germ Oil Press Maize Oil Extraction Oil Refinery Plant

1. High oil yield rate, low residual oil in meal; 2. Low labor intensity; 3. Good working environment; 4. Good meal quality. 5. Negative pressure evaporation helps to improve crude oil quality. Corn germ oil refinery plant Maize Oil Refining Machine: Crude corn germ oil → degumming and deacidification → decolorization → deodorization →

The dried germ contains about 50% oil, in which the oil constitutes about 85% of the total amount of oil present in the corn. The oil is produced by first expelling the germ and then extracting the expeller cake with n -hexane. Global annual corn production is 700 million tonnes but corn oil production is only 400 000 tonnes.

- Can absolute isopropanol be used in corn germ-bran oil extraction?

- The absolute isopropanol showed excellent performance as a solvent in corn germ-bran oil extraction, with yields above 75% from the temperature of 50 °C, in single stage batch extraction.

- How to extract oil from corn germ during flour processing?

- This work aimed the recovery of oil and protein fractions from corn germ (CG) generated as a by-product during flour processing. Several oil extraction techniques were investigated: hexane at room temperature, hexane at 45 °C, supercritical carbon dioxide (Sc-CO 2) and Soxhlet with hexane and ethanol.

- Which extraction method has the highest yield in corn germs?

- In both corn germs, the UAE extracts showed the highest yields (about 12%), followed by the extracts obtained by alkaline hydrolysis + sonication (about 5%) and by alkaline hydrolysis (about 3%). Enzymatic hydrolysis was the extraction method with lower yields (less than 1%) in both corn germs.

- Can oil and protein extracts be recovered from corn germ?

- Oil and proteins were successfully recovered from corn germ by a biorefinery scheme. Oil extraction yield and TPC of oils were influenced by the polarity of solvents. The protein content of recovered extracts ranged from 20 to 48%. The functionality of protein extracts depended on the defatting pretreatment.

- Does moisture content affect the kinetics of CGO extraction from corn germ flakes?

- The optimization, kinetic modeling and thermodynamic analysis of the CGO maceration have rarely been investigated. Up to date, only Karlovi et al. (1992) studied the influence of the moisture content and the extraction temperature on the kinetics of CGO extraction from corn germ flakes in a tube extractor (percolator).

- How is corn oil extracted?

- In the process of corn oil extraction, the germ passes through conditioning operations (heating, humidification and extrusion), to then be submitted to oil extraction by expeller (pre-pressing) and solvent extraction, with hexane being the solvent chosen by processors ( Moreau, 2005 ).

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.