Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

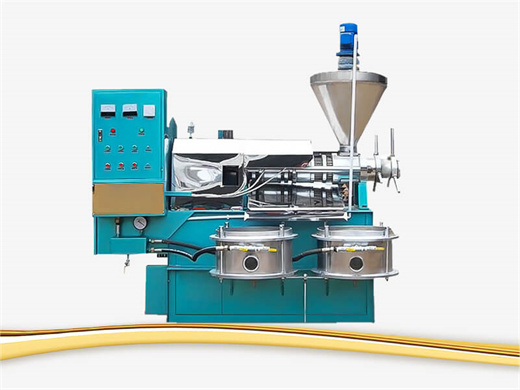

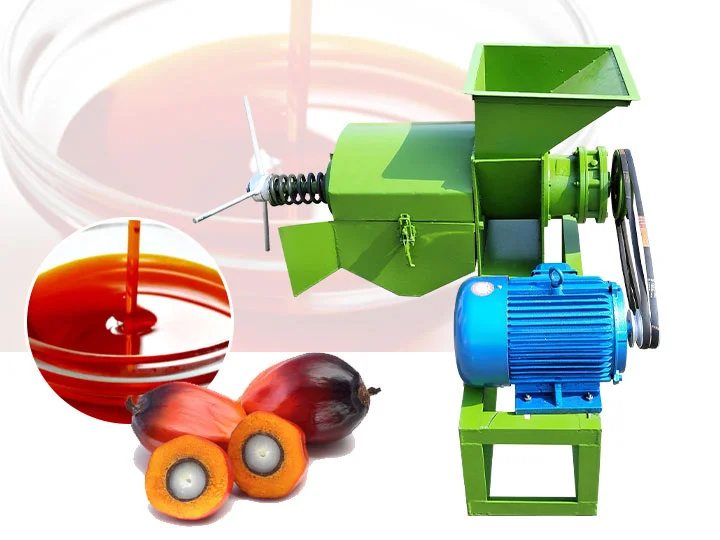

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

solvent production line kya hai in malawi

- Product Using: Producing Cooking Oil

- Type: Cooking Oil Production Line

- Main Machinery: Cooking Oil Production Line Machine

- Type:Cold & Hot Pressing Machine

- Voltage:115V/220V

- Dimension(L*W*H):63*36*46cm

- Weight:28

- Core Components:Motor

- Oil type:Flax SeedRap seed oil, Pinenut oil, sunflower seed oil, OLIVE OIL, Oil

- Raw material:Rapeseed

- Name:perilla seed oil extractor

- Function:Press Oil Seeds

- Product name:hemp pumpkin seed domestic oil extractor

- Application:Food Industry

- Advantage:Energy Saving

- Keyword:oil extractor extruder extracting machine

- Material:Stainess Steel

- Item:Vegetable Oil Refining Machines

- Feature:High Oil Yield Efficiency

- After Warranty Service:Video technical support, Online support

- After-sales Service Provided:Video technical support, Online support

- Project Location: malawi

Bakhresa Malawi | Bakhresa Group

Bakhresa Malawi limited. Bakhresa Malawi Limited was incorporated in 2003 to take over the assets of the former Government Parastatal, Grain & Milling Company Ltd (GRAMIL), under the Government of Malawi Privatisation Programme. Our business activities include the production of wheat flour and washing soap, as well as the management of Direct

1.4 Opportunities for increased Soybean production in Malawi 3. 2.0 Agronomic Practices 4. 2.1 Agro-ecologies 4. 2.2 Soybean V arieties 4. 2.3 Seed source 5. 2.4 Site selection 6.

10 Formulas for Production Calculation in the Apparel Industry

Then we will calculate capacity in number of pieces. Line capacity per day= { (No. of machine x daily work hours x 60)* (1 – absenteeism %)} x Efficiency % (capacity in minutes) Production capacity (in pieces) = Available minutes / Garment SAM. Table-6: Example of production capacity calculation. No. No. of Machines.

GC Column Solvent Retention Table. Technical Overview. Introduction. This solvent retention table provides useful data in terms of relative retention order of 275 solvents compounds on the DB-1, DB-624 and DB-WAX phases. This information is particularly useful for determining impurities in bulk solvents. A wide range of chemical functionalities

Is Each Small tesa Roll Actually Wound Separately? - tesa

Solvent- and Water-based Technology: Dissolving and mixing of the raw materials with organic solvents or water adjustment of the solids content (1). Coating (3) of the backing (2) with the dissolved adhesive. Evaporating of the solvents (4) in the drying channel (5). Winding and slitting of the tape rolls (6).

Post Tags: # Solvent in hindi # Solvent kise kahte hain # Solvent kya hai # # # # #

SOLVENT - |

"SOLVENT" : , , , , ,

Google's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languages.

OEE in Hindi | What is Overall Equipment Effectiveness

Operating Time = Planned Production Time – Downtime Time = [ 430 – 30 ] = 400 Minutes Good pieces = [Total Pieces – Reject Pieces] = [ 21955 – 215 ] = 21740 Pieces Availability = Operating Time / Planned Production Time

The Line Balance Ratio (LBR) measures the evenness of workloads across a production line. An ideal LBR is 100%, indicating all workstations have equal cycle times. This document provides an example where redistributing processes across workstations increased the LBR from 80.8% to 91.2%, eliminating the bottleneck and reducing idle time. This 10.5% increase in LBR boosted the line's throughput

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.