Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

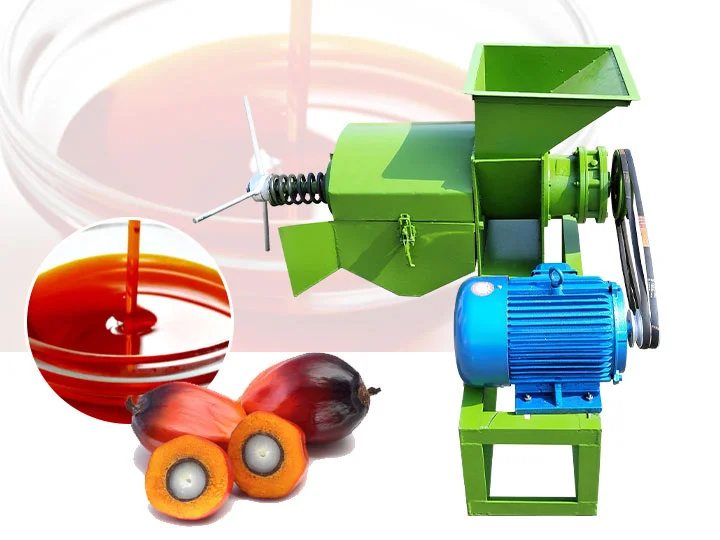

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

seed oil solvent production line for aisa in mali

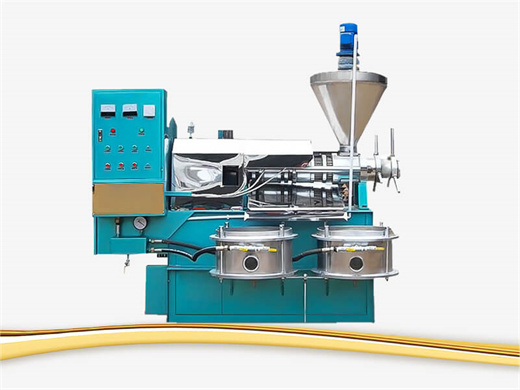

- Product Using: Producing Cooking Oil

- Type: Cooking Oil Production Line

- Main Machinery: Cooking Oil Production Line Machine

- Model NO.: YZLXQ130

- Application: All, sunflower, Rape Seeds, Flax

- Voltage: 380V

- Appearance: Horizontal

- Press Materials: Sunflower, Soybean, Coconut, Peanut, Mustard

- Press Series: Fourth

- Customized: Non-Customized

- Processing Capacity: 8 Ton Per Day

- Motor Power: 18.5kw

- Filtering Power: 1.5kw

- Oil Content of Dry Cakes: Less Than 7.6%

- Spiral Axes Rotate Speed: 32-46 Rpm

- Temperature Control Power: 3.0kw

- Measurement(L*W*H): 2120*1610*2000mm

- Advantages: High Oil Output and Easy Operation

- Function: Oil Pressing and Oil Filtering

- Weight: 1320kg

- Transport Package: Export Wooden Case

- Specification: YZLXQ130

- Project Location: mali

Equipment and turnkey plants for oilseeds crushing machine

That is why we offer oil extraction plants tailored to a variety of oilseeds. Our plants have capacities ranging from 100 t/d to 10,000 t/d, and can handle oilseeds such as soybean, rapeseed, sunflower seed, cottonseed, rice bran, peanut, corn germ, PKC (palm kernel cake), sesame, flaxseed, coconut, linseed, niger seed, shea nut, copra, avocado

The new business signed in the early of this year, we are now ready to ship these cottonseed oil making equipment to Mali according to customers' requirements. They ordered 2 sets of cottonseed dehulling lines to press cototon seed oil and make animal feed.

Expeller Pressed Sunflower Oil vs Solvent Extraction Methods

Production Process for Sunflower Seed Oil. Expeller pressed sunflower oil and solvent extraction methods are two common production processing for sunflower oil. Using the pressing method typically results in an oil residue rate of around 7%, whereas solvent extraction can reduce the oil residue rate to about 1%.

The present investigation reports the soxhlet assisted solvent extraction technique to derive the oil from seeds of the rain tree. The optimization of the factors affecting the extraction process has been carried out by Response Surface Methodology (RSM) technique, and a Box-Behnken Design (BBD) consisting of three process variables has been developed to optimize the yield of oil.

Sunflower Seed Preparation and Oil Extraction

Publisher Summary. Sunflower is crushed for oil recovery via one of two process methods, hard pressing or prepress solvent extraction. Hard pressing relies upon exerting high pressure on the prepared seed to separate oil from the solids fraction, historically recovering about 25% oil from the seed. Prepress solvent extraction relies on exerting

The main issue in developing date seed valuing is strictly correlated to oil extraction limits, in the main part from the hardness and compactness of its matrix. Thus press process for oil extraction is difficult to apply. Moreover, since the oil content is quite low, solvent extraction remains the only appropriate tool for this type of material.

Neem Seed Oil Mill Plant

Neem Seeds obtained after the Cleaning / Decortication process can be used as a raw material for Neem Seed Oil Extraction Plant. Neem seeds contain 20 – 25 % oil content. After Pressing, about 8 – 10 % residual oil is left in the oilcake/meal which is an excellent source of Natural Fertiliser.

Lower the solvent residue in the meal, adjust the meal moisture, then keep the lowest solvent consumption and meal safe use in the production. DTDC Steamed Off-line Oil extraction obeys the rule of extracting principle to obtain crude oil from various processing oilseeds.

seed oil solvent extraction machine with for and aisa

The seeds differ in that soybeans have about 20% by weight of oil, and rapeseed has about 40% oil. The higher oil products often require an added step called pre-pressing. Put simply, the high oil content makes it difficult to adequately flake the oilseed and cook it for solvent extraction without oil coming free of the seed and fouling equipment.

In this study, we aimed to evaluate oil production from safflower seeds using different kinds of solvents (diethyl ether, petroleum ether, hexane, acetone and ethanol) and extraction methods (classical solvent extraction, Soxhlet extraction and ultrasonic extraction) and compare them in terms of the process viability and the composition of

- Does Mali have a seed law?

- The law is in line with the ECOWAS seed regulation, though the level of available certified seed remains low. Mali has liberalized its economy over the past decade, resulting in a more interactive seed system with several active players from the public and private sectors, as well as farmers¡¯ organizations and non-governmental organizations.

- What are the methods of oil extraction from oil seeds?

- Conclusions Oil extraction methods from oil seeds include conventional methods (solvent and mechanical extraction) and nonconventional or improved techniques (supercritical fluid extraction, ultrasound, microwave, and enzyme assisted extraction.

- How many seed companies are there in Mali?

- The role of private seed companies remains relatively low, supplying only a small portion of the seeds that farmers use. There are 16 index companies operating in Mali, with three headquartered in the country. Only four companies accompany their sales activities with extension services.

- What is conventional solvent extraction (CSE)?

- Conventional Solvent Extraction (CSE) The conventional solvent extraction (CSE) process is amongst other factors based on the ability of the solvent to dissolve oils and to extract them from the seeds. Therefore, the solvent must be able to solubilize the oil for an efficient extraction.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.