Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

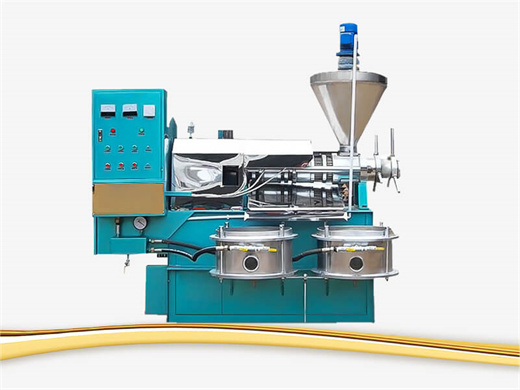

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

castor seed oil press production line by solvent way

- Product Using: Producing Castor Oil

- Type: Castor Oil Production Line

- Main Machinery: Castor Oil Production Line Machine

- Production Capacity:1-500T/D

- Model Number:1st series Doing oil fruit processing equipment

- Voltage:380V

- Power(W):according to capacity

- Dimension(L*W*H):various with capacity

- Weight:changed with capacity

- Certification:CE and ISO

- Raw material:fruit cooking oil refining machine

- Product:to make crude oil or refined oil

- Solvent name:n-hexane

- Capacity:from 5T to 2000T oil fruit processing equipment

- Oil content in peanut:about 40%

- Oil residues:less than 1%

- Function:getting oil

- Manufacturing experience:19 years experience in edible oil field

- Warranty:12 months

- Material of equipment:stainless steel and carbon steel

Castor Oil Manufacturing Process Flowchart

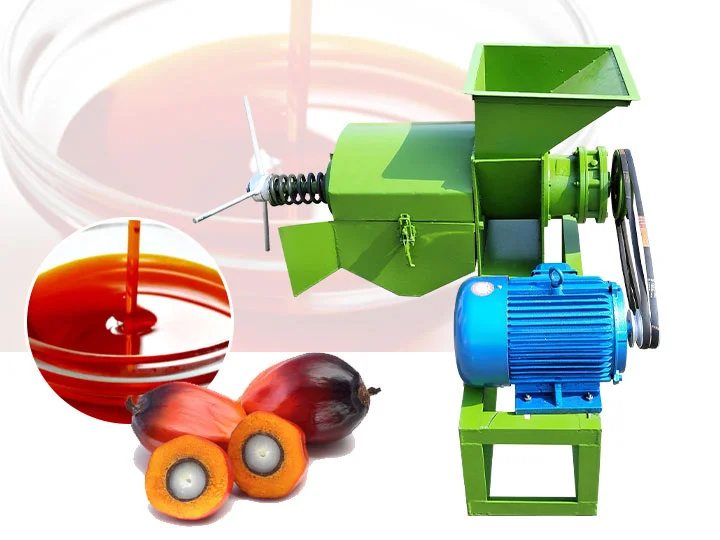

Here are the basic steps to extract the castor oil. Step 1: Castor Seed Dehulling. Step 2: Castor Seed Cleaning. Step 3: Castor Seed Cooking. Step 4: Castor Seed Pressing. Step 5: Castor Oil Clarification. Step 1: Castor Seed Dehulling. Castor seed contains about 30%–35% oil. The extraction process begins with the removal of the hull from the

Castor oil seed contains about 30%–50% oil (m/m).74,75 Castor oil can be extracted from castor beans by either mechanical pressing, solvent extraction, or a combination of pressing and extraction.74 After harvesting, the seeds are allowed to dry so that the seed hull will split open, releasing the seed inside. The extraction process begins

Optimization of Process Parameters for Castor Oil Production

M. Belaid is with the Department of Chemical Engineering, Faculty of Engineering and the Built Environment, University of Johannesburg, Doornfontein, Johannesburg 2028; phone: 0027-11-5596402; fax: 0027-11-5596430; e-mail: mbelaid@uj.ac.za. extracted from castor beans by either mechanical pressing or solvent extraction or combination of the two.

As with most oilseeds, the castor oil production process begins with dehulling and cleaning the beans to remove shells, stems, and other foreign materials. Oil processors then heat batches of dehulled castor beans in steam-jacketed cookers or forced hot air vessels to remove moisture and harden the seeds for more effective mechanical pressing.

Castor Oil: Properties, Uses, and Optimization

Castor oil, produced from castor beans, has long been considered to be of important commercial value primarily for the manufacturing of soaps, lubricants, and coatings, among others.

Castor seed entering in the industry has approximately 48% of oil content (Severino et al., 2015), and the castor cake sampled just after the expeller press had the oil content reduced to 10.96% ± 1.93 (Table 2). The extraction with solvent reduced the oil content of the wet castor meal to 1.71% ± 0.57 (Table 2).

Extraction, Characterization and Modification of Castor Seed Oil

extraction. However the most satisfactory approach is hot pressing using a hydraulic press, followed by solvent extraction [1, 3]. However, castor oil and its derivatives are used in the production of paints, varnishes, lacquers, and other protective coatings, lubricants and grease, hydraulic fluids, soaps, printing

In literature, various attempts were made to optimize castor oil recovery. The optimum results were a recovery and moisture content of 48.75% and 5.8% respectively [2, 4, 5, 6]. The objective of this study was to optimize castor oil recovery from castor beans obtained from Mpumalanga Province of South Africa. II.

EXTRACTION AND CHARACTERIZATION OF CASTOR SEED OIL - IJSER

ABSTRACT: Extraction and characterization of castor seed, the seeds were prepared for use by removing the endocarp, sun-drying for seven days and milled to flour. A soxhlet extraction was used for the extraction of oil, using hexane as solvent. The oil was recovered by simple distillation of the solvent.

This work is focused in the study of the oil yield extraction from castor seed using three different seed states called: whole, broken and bare endosperm. Taguchi design was used to determine the

- What is castor seed oil production line?

- This castor seed oil production line adopts mechanical oil pressing technology. It connects a series of seed processing equipment to continuous oil extraction which can largely saving labor cost in production. The castor oil seeds undergoes many processes to produce castor oil.

- How Castor oil is produced?

- It connects a series of seed processing equipment to continuous oil extraction which can largely saving labor cost in production. The castor oil seeds undergoes many processes to produce castor oil. The following steps: seed cleaning, seed cooking, oil extraction, oil clarification, oil storage and filling. Step 1: Castor Seed Dehulling

- What is the extraction and characterization of castor seed oil?

- EXTRACTION AND CHARACTERIZATION OF CASTOR SEED OIL ABSTRACT: Extraction and characterization of castor seed, the seeds were prepared for use by removing the endocarp, sun-drying for seven days and milled to flour. A soxhlet extraction was used for the extraction of oil, using hexane as solvent.

- How to get castor oil?

- However, the most satisfactory approach to get the oil is hot pressing the castor seeds by using a hydraulic press and then followed by solvent extraction (Ogunniyi, 2006). The leading producers of castor seed and the countries that seriously involve in the production of castor oils are India, China, and Brazil.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.