Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

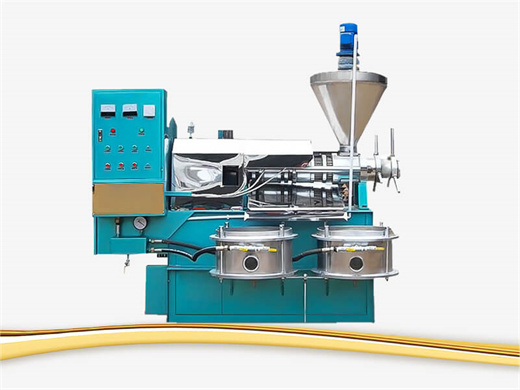

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

edible oil soybean oil refining production line in lagos

- Product Using: Producing Soybean Oil

- Type: Soybean Oil Production Line

- Main Machinery: Soybean Oil Production Line Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: high

- Model Number: soybean oil refinery equipment China alibaba

- Voltage: 220V, 380V, or other

- Power(W): depend on the capacity

- Dimension(L*W*H): depend on the capacity

- Weight: depend on the capacity

- Certification: CE, ISO9001, BV

- After-sales Service Provided: Engineers available to service machinery overseas

- Phosphoric acid: 2~3kg/T oil

- Electric consumption: 28kwh/T oil

- certification: CE, ISO9001, BV, etc..

- Steam consumption: 450kg/T oil

- Deodorization loss consumption: ≤0.5%

- color: depend on the requirements of the clients

- condition: new soybean oil refinery equipment China alibaba

- Waste bleaching earth oil content: <35%

- Bleaching earth consumption: 5~50Kg/Toil

- capacity: based on the need of the clients

- Project Location: lagos

Oil Refinery, edible oil refinery Technology and Equipment

CHEMSTA vegetable oil&fats refining production line is used to refine various oils, including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, corn germ oil, and rice bran oil. This production line features a capacity of 30-1,000 tons of crude oil per day, and is able to eliminate plasticizer (DEHP) pollution and

First in oil with HongdeMachinery. Reliable seed oil processing equipment covering all steps of refining for any type of edible seed oil. Oilseed processing solutions for boosting capacity, limiting loss and increasing yield, creating new profitable possibilities. Improved sustainability and reduced operational costs thanks to unique technologies

A Step-by-Step guide For Edible Oil Production From Soybean Seeds

Production of soybeans expanded from the southern part of the United States. 1950-70's. The U.S. accounted for more than 75% of global soybean production. 1970's. Production of soybean started at a large scale in many South American countries. 2003. The share of the U.S. in global soybean production came down to 34%.

in good quality soybean seed oil production line in lagos. Usage: Soybean Oil, Cooking Oil; Type: Cooking Oil Press Machine; Production Capacity: 210kw; Voltage: 380v; Dimension(L*W*H): 8*2*4m; Weight: 6 KG, 6T; Core Components: Motor, Pressure vessel; Oil type: Soybean Oil; Name: Soybean oil Production Line / edible oil refining machine

Soybean Oil Refining Process Unveiled | Expert Guide

Soybean Oil Processing and Main Edible Oil Refining Machinery. The comprehensive soybean oil production process can be broadly segmented into: seed cleaning, moisture conditioning, crushing, softening, flaking, extraction, refining, and packaging. Therefore, a diverse array of equipment is necessary to successfully navigate these stages.

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil. The […]

Edible oil refining process systems

Our edible oil production process line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route.

Abstract. Population growth is driving the search for new food sources, including entomophagy, i.e., a diet based on edible insects. Insect powder are rich in essential fatty acids, minerals, vitamins, and bioactive compounds such as antioxidant phenolics. The technologies for extracting oil from insects must be efficient to guarantee high yields.

SEPARATION TECHNOLOGY FOR EDIBLE OIL REFINING - GEA

Edible oil = GEA core business. Two processes have been developed for refining edible oils and fats; the decision as to which process is to be used de-pends on the types and qualities of crude oil to be processed. Chemical refining is the traditional method, where the free fatty acids of the crude oils are neutralized with caustic soda.

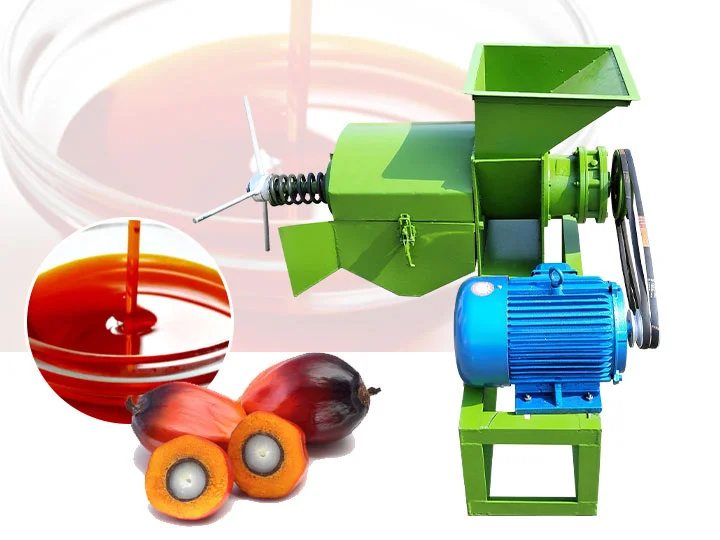

Palm oil, derived from Elaeis guineensis, is a critical component of the global edible oil and industrial fat market. This review provides a comprehensive overview of the sustainability of the palm oil chain, focusing on industrial applications, environmental implications, and economic sustainability. The processing of palm oil, from fruit pulp to refined oil, is detailed, highlighting the

- How do you turn crude oil into edible oil?

- Refining crude oil into edible oil requires deep process knowledge¡ªfrom degumming, neutralization and dewaxing to bleaching, deodorizing and GE and 3-MCPD mitigation. The Tampieri family has been producing grapeseed oil for more than 90 years. By using Alfa Laval products, their production becomes both efficient and sustainable.

- What is edible oil bleaching?

- Deodorization of oil, stripping them of unwanted odour, flavour, colour and other unwanted volatile substances, as well as the formation of glycidyl esters (GEs) & trans-fatty acids (TFA) isomers. Solutions for optimal edible oil bleaching process, built on deep process knowledge and global services.

- What is a neutralization system for edible oil?

- Systems for neutralization of edible oil to remove free fatty acids and other impurities that impact edible oil quality, consistency, appearance, taste and shelf life.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.