Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

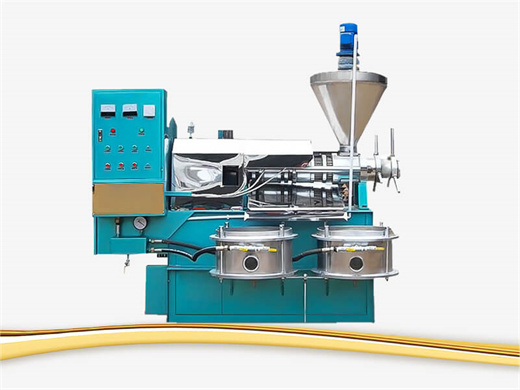

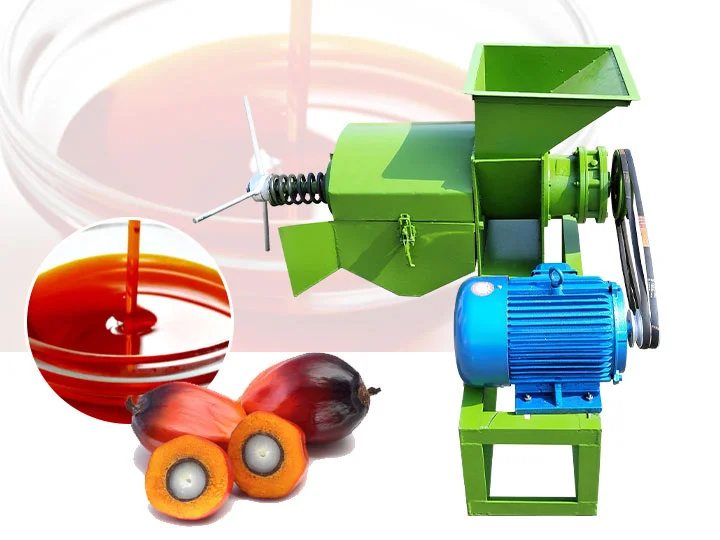

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

crude oil refinery soybean oil production line in lagos

- Product Using: Producing Soybean Oil

- Type: Soybean Oil Production Line

- Main Machinery: Soybean Oil Production Line Machine

- Automatic Grade: Semi-Automatic

- Production Capacity: 100-4000TPD

- Model Number: LD-X

- Voltage: 220V / 380V / 440V

- Power(W): 15KW

- Dimension(L*W*H): 1200*2800*1200mm

- Weight: 1200 Tons

- Certification: CE/ ISO/ BV

- After-sales Service Provided: Engineers available to service machinery overseas

- solvent consumption: 1.5Kg/Ton raw materials

- Oil Color: Yellow

- Oil getting method: pressing/extraction

- Heating way: direct & indirect steam

- Advantage: save water resource

- Bleaching earth consumption: 5~50Kg/T oil

- Steam consumption: very low

- decolor function: to get good color

- deodor function: remove the bad smell

- Project Location: lagos

Case study of chemical and enzymatic degumming processes

The vegetable oil degumming process plays a critical role in refining edible oil. Phospholipids (PL) removal from crude extracted soybean oil (SBO) by the enzymatic degumming process has been

In edible oil refining, the continuous effort to reduce overall production costs is mainly achieved by increasing plant capacities, installation of mono feedstock plants, and increasing the degree of automation. Over the years, more energy-efficient processes and technologies, resulting in a higher refined oil yield, have gradually been introduced.

top 10 soybean oil expeller for sale in lagos

How is soybean oil extracted? Two common soybean oil production processes are solvent extraction (chemical) and mechanical extraction using a screw press. The most conventional method is to extract oil by mechanical oil processing machines. The oil obtained from screw press, known as crude oil, usually undergoes a filtration process before being consumed as food. What is […]

The refining of soybean oil, a process that removes impurities and enhances its stability, is a crucial step in ensuring the oil's superior quality. With its demand steadily increasing across industries, the market for soybean oil and its refined products is poised for further growth. Besides, the refining process, which transforms crude

Soybean Oil Production Line Overview - Edible Oil Expeller

The soybean oil production line is the process of treating soya bean with the press method or leaching method to obtain more crude oil and then refined to obtain edible refined oil. Pressed soybean oil has natural colors, aromas and flavors, and retains raw material’s various nutritious ingredients when comparing with the leached oil. The

Our edible oil production process line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route.

A Step-by-Step guide For Edible Oil Production From Soybean Seeds

Production of soybeans expanded from the southern part of the United States. 1950-70's. The U.S. accounted for more than 75% of global soybean production. 1970's. Production of soybean started at a large scale in many South American countries. 2003. The share of the U.S. in global soybean production came down to 34%.

Oil type: Soybean Oil; Product name: screw oil press equipment with vacuum filter; Capacity: 1TPD-1000TPD; Material of epuipment: stainless steel and carbon steel; Final product: cooking oil; Application: all kinds of crude oil; Advantage: high oil out rate ,low oil loss; Residual oil: less than 1%; Color: As customized

Soybean oil refining production line Process - Edible Oil

Soybean oil refining process:. 1. Hydration Degumming & Alkali Refining Deacidification Process. Neutralization: The crude oil is output by the oil feed pump from the oil tank, and enters the crude oil heat exchanger to recover part of heat after metering and then is heated to the required temperature by the heater.

Dangote refinery is a 650,000 barrels per day (bpd) integrated refinery and petrochemical project under construction in the Lekki Free Zone near Lagos, Nigeria. It is expected to be Africa’s biggest oil refinery and the world’s biggest single-train facility, upon completion in 2022. The refinery will process a variety of light and medium

- How many barrels of oil does Lagos refinery produce a day?

- The refinery, which occupies 2,635 hectares of land in the Lekki Economic Free Zone in Lagos and has a capacity to process 650,000 barrels of oil per day, began producing diesel, kerosene and aviation fuel on January 12.

- Is Nigeria's first oil refinery a game-changer?

- The $19 billion facility, which has a capacity to produce 650,000 barrels per day, has started to produce diesel and aviation fuel, the Dangote Petroleum Refinery company reported Saturday. As Nigeria¡¯s first privately owned oil refinery, the project ¡°is a game-changer for our country,¡± it added.

- Will Nigeria's biggest oil refinery boost refining capacity?

- (AP Photo/Sunday Alamba, File) ABUJA, Nigeria (AP) ¡ª Africa¡¯s biggest oil refinery has begun production in Nigeria, the company has said, ending a yearslong wait for a plant that analysts said Monday could boost refining capacity in a region heavily reliant on imported petroleum products.

- Where is Africa's biggest oil refinery?

- Africa¡¯s biggest oil refinery has begun production in Nigeria after a yearslong wait. The $19 billion Dangote Petroleum Refinery facility has a capacity to produce 650,000 barrels a day and has started to produce diesel and aviation fuel, the company reported Saturday.

- How many jobs will be created through Nigeria's oil refinery project?

- More than 100,000 direct and indirect jobs are expected to be created through the project, the Lagos State government has said. After several years of delays, Africa's largest oil refinery was commissioned Monday by the outgoing Nigeria's President Muhammadu Buhari.

- What is Dangote oil refinery?

- Dangote Oil Refinery is a 650,000 barrels per day (BPD) integrated refinery project under construction in the Lekki Free Zone near Lagos, Nigeria. It is expected to be Africa¡¯s biggest oil refinery and the world¡¯s biggest single-train facility.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.