Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

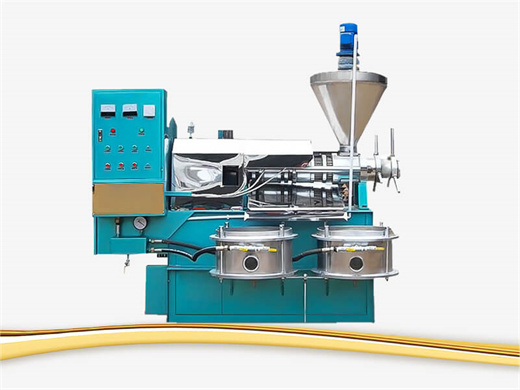

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

20tpd edible palm oil refinery production plant in botswana

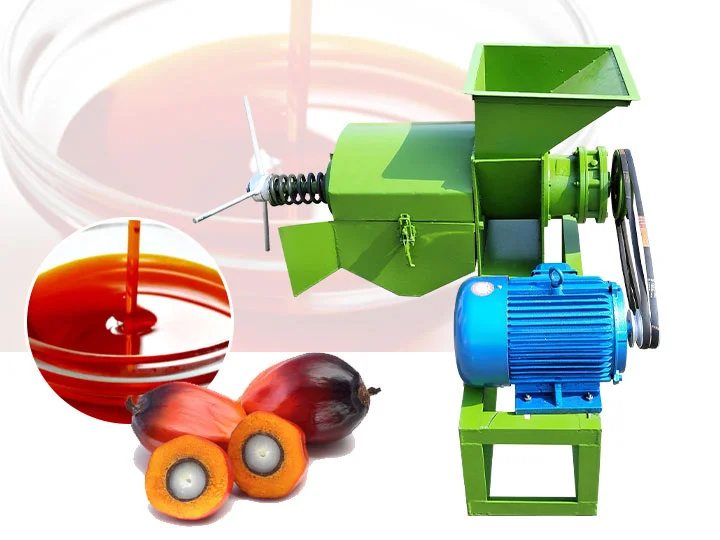

- Product Using: Producing Palm Oil

- Type: Palm Oil Refinery Plant

- Main Machinery: Palm Oil Refinery Plant Machine

- Automatic Grade: Automatic

- Production Capacity: 100%

- Model Number: DT

- Voltage: 220V/380V

- Power(W): 10-50kw

- Dimension(L*W*H): According to the capacity

- Weight: According to the capacity

- Certification: ISO9001/CE/BV

- After-sales Service Provided: Engineers available to service machinery overseas

- Item: High Quality Edible Crude Palm Oil Refining Machine/Refinery

- Voltatile substance in crude oil: ≤0.3%

- Clay consumption: depending on color of crude oil

- Solvent contain in crude oil: ≤200ppm

- Oil residue in waste clay: ≤25% of waste clay

- Performance: Excellent

- Steam pressure: ≥1.2MPa

- Steam consumption in refining: ≤280kg/ton

- Warranty: 12 Months, long term technical support

- Feature: High Output

- Project Location: botswana

oil refining – edible oil production plant in Botswana

United Refineries Botswana (URB) is the first cooking oil manufacturing company in Botswana. It has a manufacturing plant with a capacity of producing up to 70 tons / day. Edible Plant Oil: Global Status, Health Issues, and Perspectives. Edible plant oil (EPO) is an indispensable nutritional resource for human health. Various cultivars of oil

Edible Oils - Botswana. Revenue in the Edible Oils market amounts to US$128.00m in 2024. The market is expected to grow annually by 9.36% (CAGR 2024-2029). In global comparison, most revenue is

What is the most suitable palm oil refining equipment for a 20tpd palm

The most suitable palm oil refining equipment for a 20tpd palm oil refinery plant is batch palm oil refining equipment. But if you want to pursue long-term comprehensive benefits in the future, semi-continuous palm oil refining equipment and continuous palm oil refining equipment are good choices. You can choose according to your ability and needs.

MeTL Group, through East Coast Oils and Fats, boasts 60% of the total market share in edible oil sales from the plant’s 45,000 metric tons production monthly. East Coast Oils and Fats currently has three oil refineries capable of refining 2400 metric tons per day (over 70,000 metric tons per month), a manufacturing line of soaps with an

A Comprehensive Guide to the Edible Oil Refining Process.

The process begins with heating crude palm oil (CPO) to a specific temperature, typically around 70-75°C (158-167°F). This heating reduces the viscosity of the oil, making it more fluid and easier to work with. Crystallization: After heating, the CPO is gradually cooled down under controlled conditions.

Our Batch-Type Edible Oil Refining plants are designed for capacities ranging from 1 ton per day (TPD) to 20 TPD, making them suitable for small producers and pilot operations. This edible oil refinery plant includes the crude oil degumming, neutralizing, bleaching, and deodorizing process. With its cost-effective design and ease of use, this

Turnkey Project of Palm Oil Refinery Plant|Physical Refining

Basic Steps of Edible Oil Refining Process. Step 1: Remove the easily hydratable phospholipids by degumming with water. Step 2: Convert the remaining on-hydralable phospholipids into hydratable phospholipids. Step 3: Adding a slight excess of sodium hydroxide solution to neutralize the free fatty acids.

The main processes of palm oil refining process are: degumming, deacidification, decolorization and deodorization. Therefore, we should consider the characteristics of different raw edible oils and then choose the best refining method. For crude palm oil, we usually use physical refining to remove FFA. Let me introduce the refining process of

10-100tpd edible oil production plant in Botswana

100kg/h 20tpd oil refinery plant project Botswana. Set up a Soybean oil refinery plant with low cost, soya bean. They are: 1-20tpd batch type soybean oil refinery plant; 20-50tpd semi-continuous type soybean oil refinery plant; 30-1000tpd full-continuous type soybean oil refinery. 100tpd coconut oil mill for sales in botswana - Edible Oil

The refining process of palm oil includes the following: Bleaching. Deodorisation. Fractionation. The crude oil is refined using two methods, including physical refining and chemical refining, during which FFA is removed to ensure that the FFA content is not more than 0.1 %. It is essential to note that physical refining is environment-friendly

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.