Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

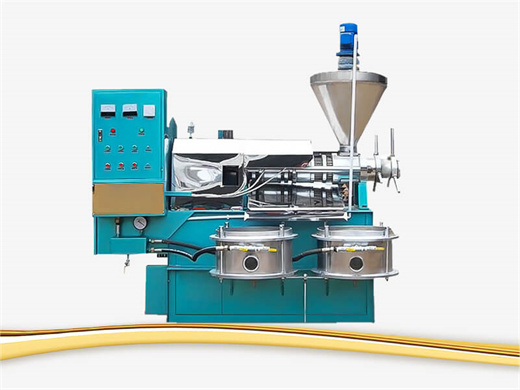

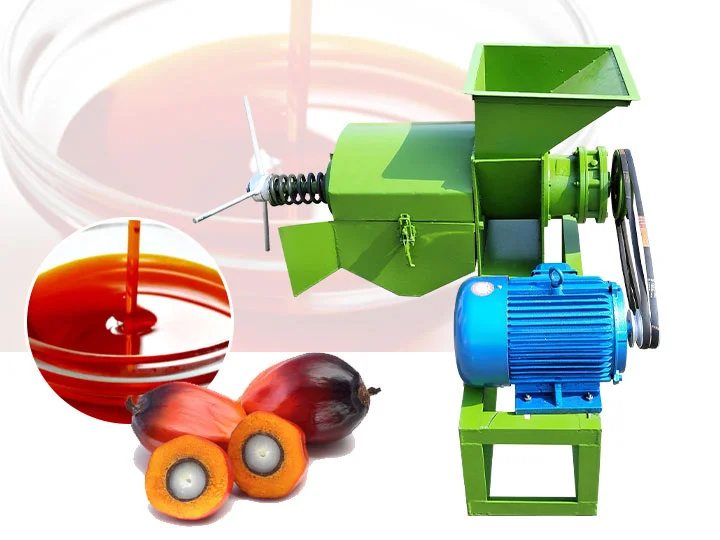

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

small capacity oil bleaching equipment/oil refinery plant

- Product Using: Producing Cooking Oil

- Type: Cooking Oil Refinery Plant

- Main Machinery: Cooking Oil Refinery Plant Equipment

- Automatic Grade: Automatic

- Production Capacity: 95%

- Model Number: HT-RBOM

- Voltage: 380V/220V

- Power(W): 85000

- Dimension(L*W*H): 10M*6M*5M

- Weight: 10T

- Certification: ISO9001

- oil refining machine: Oil refining machine

- Specification: 2~1000T/D

- Oil: Peanut oil,oil, oil, oil.

- Grade of refined oil: The best grade

- Materials: Carbon steel and stainless steel

- Technology support: Invention patent product

- Enterprise strength: Strong R & D Team

- Brand: TOP 10 oil refining machinery Brand in China

- Projects: Thousands of oil palnts are using our machines.

- Installation and Debugging: We instruct installation, debugging and training workers.

Small-sized Oil Refinery Machinery

Type: Crude Oil Refinery Plant Processing Capacity: 1-5T / D Processing Material: Palm Oil, Palm Kernel Oil, Peanut Oil, Rapeseed Oil, Cottonseed Oil, Sunflower Oil, Corn Germ Oil, Animal Oil etc. Small Scale Oil Refining Plant Process Flow: Crude Edible Oil—–Degumming—–Neutralizing—–Bleaching—–Deodorizing—–Edible Oil. Small

Oil Bleaching. Oil bleaching is carried out before deodorization in an edible oil refinery. The process removes color, as well as residual phosphatides, metals and soaps. To do this, clay is added to the oil then heated, upon which it absorbs pigmentation. Lastly, the oil-clay mixture is filtered and the spent cake is dried to remove the oil.

Cooking Oil Refining Plant. Edible Oil Refining Equipment. Oil Solvent

Capacity Range: Our refinery plants range from 2 to 5,000 tons per day (TPD), accommodating various production scales.; Custom Solutions: We provide tailored refining solutions based on the specific characteristics of different crude oils, such as palm oil, soybean oil, sunflower seed oil, peanut oil, rapeseed oil, corn germ oil, cottonseed oil, linseed oil, and rice bran oil.

Features of Batch Type Edible Oil Refining Equipment. Compact Setup: The equipment is designed to be modular, making it easy to install, operate, and maintain. Flexible Configuration: Allows for easy modification to handle various types of crude oils and refining processes. Batch Processing: Operates in batches, ideal for small-scale edible oil

Small Scale Edible Oil Refinery Equipment for Oil Mill Plant. Batch

This batch-type oil refinery plant is the best choice for small edible oil plants. The capacity ranges from 1 TPD to 10 TPD. It can process almost all the edible oil. The oil refining equipment can work independently or combine with the entire edible oil production line.

Our Batch-Type Edible Oil Refining plants are designed for capacities ranging from 1 ton per day (TPD) to 20 TPD, making them suitable for small producers and pilot operations. This edible oil refinery plant includes the crude oil degumming, neutralizing, bleaching, and deodorizing process. With its cost-effective design and ease of use, this

Oil Refinery Equipment for Refining Vegetable Oil at Best Price, Oil mill

Small Scale Edible Oil Refinery Plant. This batch-type oil refinery plant is the best choice for small edible oil plants. The capacity ranges from 1 TPD to 10 TPD. The complete edible oil refining process mainly includes filtration, degumming, deacidification, vacuum dehydration, decolorization, deodorization, dewaxing, and polishing filtration.

The Imcopa soybean oil refinery in Brazil decided on an upgrade path to tackle very high steam costs, plus problems with poor heat recovery in the company’s existing plant. Benefiting from the HongdeMachinery retrofit concept, Imcopa upgraded an existing deodorizer and installed a new neutralization and bleaching line , plate heat exchangers, mixers and a PX 95 separator .

Batch Oil Refinery Plant for Edible Oils, Oilmillmachinery.net

batch oil refinery. Batch oil refinery is quite suitable for small capacity vegetable/edible oil making plant, which capacity ranges from 1TPD to 20TPD. These batching stages are Degumming, Neutralizing, Decolorization and Deodorization. Continuous refinery is another method used to purify vegetable oil but in this case we will focus more on

Small oil refinery plant we designed is a well sell refining line for either vegetable or animal oils. It is suitable for smaller capacity oil refinery. The smaller plant is able to remove phospholipids, FFA, pigment, gums, waxes, off-flavor and other impurities in the oil. It can also process a great number of vegetable seeds oils like soybean

- What is tiny technology machinery plant?

- Amidst all the above, TINYTECH has tried a bit to develop Tiny Technology machinery plants which are economical and viable. ¡°Small Scale Oil Refinery Plant¡± is an innovative Oil Refining Unit for the Edible as well as Non-Edible Oils. Our research to invent the small scale refinery in early 20¡¯s resulted into a great achievement.

- What is bleaching process in vegetable oil refining?

- Bleaching Process is the third step in vegetable oil refining which commences after complete of effective neutralization process. Bleacher Pressure Vessel is used to carry out the Bleaching Process. A Bleacher is careful designed equipment based on design parameters to ensure perfect bleach-ability of the crude oil.

- What is a bleach pressure vessel?

- Bleacher Pressure Vessel is used to carry out the Bleaching Process. A Bleacher is careful designed equipment based on design parameters to ensure perfect bleach-ability of the crude oil. The process has its own importance. The purpose of Bleaching is to remove the color pigments contained inside Vegetable Oils.

- How is edible oil bleached?

- Oil bleaching is carried out before deodorization in an edible oil refinery. The process removes color, as well as residual phosphatides, metals and soaps. To do this, clay is added to the oil then heated, upon which it absorbs pigmentation. Lastly, the oil-clay mixture is filtered and the spent cake is dried to remove the oil.

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.