Please feel free to contact us if you are interested in our products or want to know more details or the latest price. We sincerely hope to cooperate with customers all over the world! Send your inquiry now!

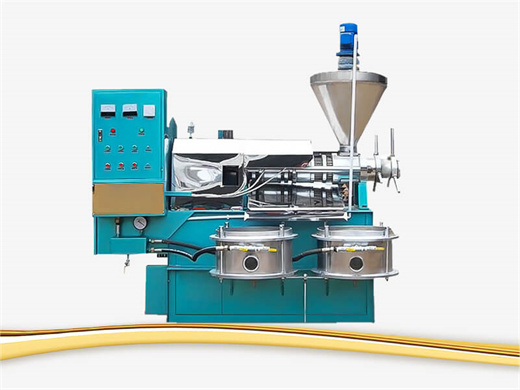

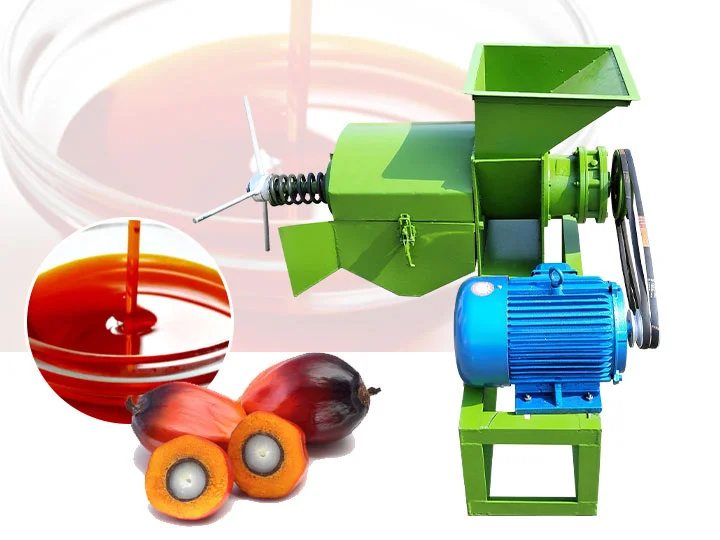

Cooking oil processing machines which can process various oil seeds, including peanut, soybean, sunflower seed, palm, palm kernel, sesame, rapeseed, cotton seed, etc.,

crude vegetable oil refinery plant machine for many oilseed materials

- Product Using: Producing Vegetable Oil

- Type: Vegetable Oil Refinery Plant

- Main Machinery: Vegetable Oil Refinery Plant Machine

- Production Capacity:As Oil Refinery Machine capacity

- Model Number:Oil Refinery Machine

- Voltage:As Oil Refinery Machine capacity, 220V or 380V

- Power(W):As Oil Refinery Machine capacity, Accoding to your capacity

- Dimension(L*W*H):As Oil Refinery Machine capacity

- Weight:As Oil Refinery Machine capacity

- Certification:ISO9001

- Item:pump used in oil refinery

- Color:As Oil Refinery Machine capacity capacity

- Processing:Oil press ,extraction ,refinery

- Phosphoric acid:2~3 kg/T oil

- Refining rate:Refining consumption 1%

- Supplier type:Manufacturer

- Waste bleaching earth oil content:25% to 35 %

- Soften water:150Kg/T oi

Oils Fats Refining Equipment and Turnkey Plants

Worldwide, Myande has supplied more than 500 oilseed crushing lines and more than 150 oil refinery lines, including 30 oil refinery production lines with capacity above 800t/d and 20 oil refinery production lines with capacity above 1,000t/d. The picture below shows location refinery plant equipment Myande has supplied.

Second Stage of Vegetable Oil Refining Process. Neutralization or simply Neutralizing is the second process in the vegetable oil refining which commences after degumming completion. The feedstock is taken into the Neutralizers where the heating temperature range is kept at 55 C to 70 C depending on the quality of crude oil.

Refining Vegetable Oils: Chemical and Physical Refining

So, tocopherols decrease in vegetable oils substantially and directly influence decrease in the shelf life of oils and the nutritional quality [20, 22]. In this context, such refining process for crude oils should be undertaken with the aim of removing undesirable compounds and avoiding the least possible damage to desirable components [14, 23].

Edible oil refining is the process of converting raw vegetable oil into edible oil. Raw vegetable oils, whether obtained through pressing or solvent extraction, contain unwanted components such as free fatty acids, phospholipids, and others, which cause undesirable flavors, odors, and appearances. As a result, refinement is required

Oil Refinery, edible oil refinery Technology and Equipment

1. Degumming and Neutralization Section:. Equipment: mixer, reactor, heat exchanger, acid and alkali dosing device, separator, vacuum dryer, vacuum system. Features: For specific kind and grade of crude oil , the degumming and neutralization process can be flexibly adjusted to improve product yield. Physical refining process is suitable

Our edible oil production process line portfolio. After oil clarification (for pressed oils), the oil can be refined as shown below. The crude oil is then transferred either to special degumming in the physical refining route, to water degumming, or directly to neutralization in the chemical refining route.

Production process, methods of extraction, and refining

For the refining of crude vegetable oils, there are two main routes: the chemical and the physical refining. Some by-products of low commercial value are obtained through these refining processes. Important amounts of by-products such as soapstock, deodorizer fatty acid distillates, and acid oil are produced from the oil refining processes

2. Deacidification: The deacidification process used in small scale vegetable oil refinery plant is to remove Free Fatty Acid (FFA) is by alkali refining. Based on the principle of acid-base neutralization, heat crude oils firstly, and then add alkali liquor, to agitation mix and settle. Then separate out the soap stock from crude oils.

Edible vegetable oils from oil crops: Preparation, refining

Refining of vegetable oils. The refining process can remove many undesirable components, including free fatty acids, oxidation products and photosensitizers. It is worth noting that some beneficial components are also removed, such as carotenoids (mainly including α- and β-carotene) and tocopherols (such as tocols and tocotrienols) [45]. Thus

The oil waxes are minor compound present in crude oils in variable content ranging from 950 to 1090 ppb in industrial sunflower oil (Carelli, 2002) and their presence affects the clarity and cold

- Which industrial technologies are used for vegetable oils' refining?

- The present review aimed at comparing the two main industrial technologies used for vegetable oils¡¯ refining, namely, chemical refining and physical refining. Chemical refining removes free fatty acids by soda neutralization.

- What is crude oil refining?

- Treatment that eliminates undesirable and toxic components in crude oils is known as ¡°refining¡± [ 9 ]. Refining is practically mandatory for crude oils that cannot be consumed as virgin oils to provide a product with an attractive appearance, a neutral taste, and more resistance to oxidation.

- How does refining affect the stability of refined edible oils?

- This directly influences the stability of refined edible oils. Efficient refining processes should be developed for crude oils to remove undesirable compounds while doing the least possible damage to the interesting components at the same time and not generating higher levels of unwanted compounds.

- Why is degumming important in vegetable oil refining?

- Degumming is a crucial step in the refining process of vegetable oils [ 9 ]. It allows the elimination of ¡°gums¡± or ¡°mucilage,¡± composed mainly of phospholipids from the crude oil as well as compounds such as carbohydrates, proteins, and trace of metals [ 9, 34 ]. Phospholipids or phosphatides are naturally present in oils.

- What is the final step in the Physical refining of oil?

- The final step in the physical refining of oils is deacidification and deodorization. Oils are deodorized under the conditions described above for chemical refining. Removal of volatile components such as free fatty acids, different off-flavors, contaminants (pesticides, light polycyclic aromatic hydrocarbons, etc.).

- How is crude oil made?

- During the process, crude oil is pretreated with a combination of citric acid and caustic soda. It is then mixed with water and an enzyme (Lecitase Ultra) using a high shear mixer. This creates a very stable emulsion that can be broken by centrifugation then separated into phospholipids and mucilaginous materials from the oil [ 45, 47 ].

REQUEST A QUOTE

You Can Write Down Your Requirements! Submit your enquiry, we will reply your quote within 24 hours.